DATA SHEET

Owner: Nike

Architecture & Interior design: Olson Kundig, Tom Kundig, Kirsten Ring Murray

Furnishings: Arper, Athletic Seating, Magis, Winnebago; custom made furniture by Made-Studio & RAD; custom cabinetry designed by Olson Kundig and built by GC

Environmental graphic led: Nike, in collaboration with Olson Kundig and Studio Matthews

Graphics: Nike

Photo credits: courtesy of Nike

“Our mission is what drives us to do everything possible to expand human potential.” Nike’s mission statement contains the inspiration and innovation that spurred Phil Knight to found this brand that has become the definition of an icon, which Nike, true to its nature, wants to bring to every athlete. These are the core principles behind the building of the new LeBron James Innovation Center inside the Nike World Headquarters, in Beaverton (Oregon).

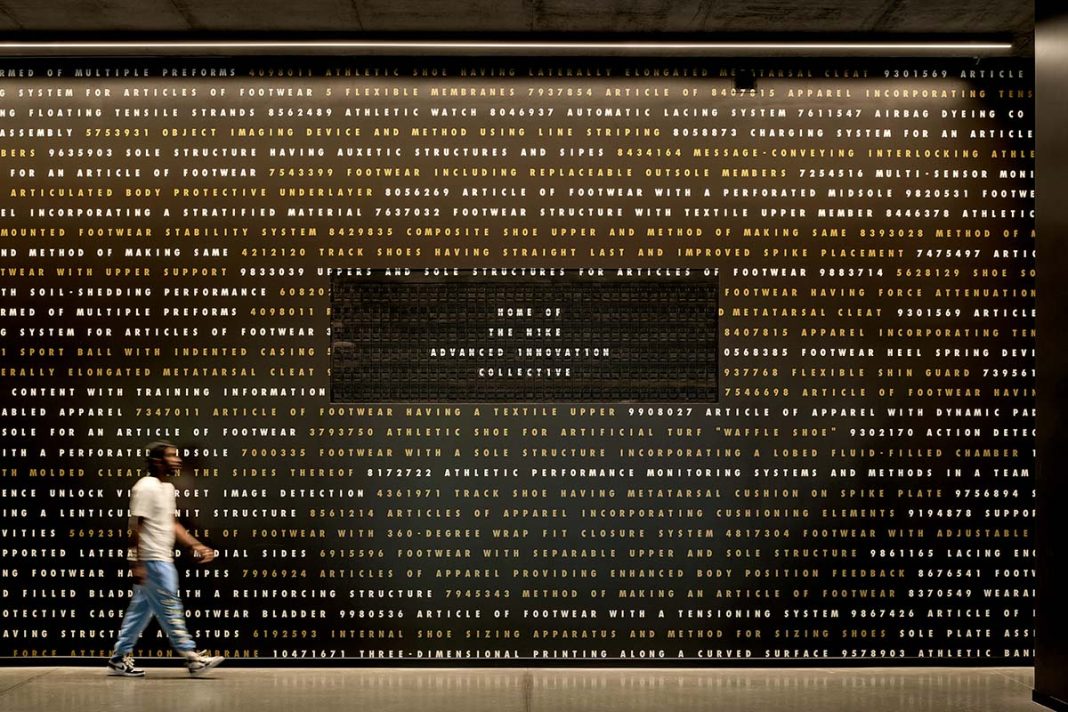

The building — named for the four-time NBA champion and four-time MVP with which Nike has a lifetime deal — brings together Nike’s innovation teams that had been spread over the 286 acres of the Nike Campus with the goal of fostering interconnections and the cross-pollination of ideas. design studios, offices and meeting spaces, prototyping laboratories, an internal research facility and even a 100-meter sloping outdoor track makes for a highly functional hub where the latest innovations in sports technology can be designed, built, tested and perfected.

The project was designed by the Seattle-based studio Olson Kundig, which envisioned the space’s architecture (with its 700,000 sqf) as a rectangular volume soaring horizontally to become a metaphor for the concept of speed.

Tom Kundig, the firm’s Design Principal with Jim Olson explains, “The ‘big idea’ behind this building is Nike’s underlying agenda of fast. Athletics at all levels, and innovation in service of athletes, is about capturing speed, about going fast. The spiritual sense of the building reflects this functional basis as well as the poetic finish of fast.”

This concept is expressed inside through a large central atrium, open across the four floors, removing physical barriers to facilitate collaboration, spontaneous meetings and co-working. A large staircase connects the floors up to the top one, all of which is the Nike Sport Research Lab (NSRL), which cantilevers out from the monolithic structure at 50 feet high and covers the main entrance. This makes visible the precision cement “waffle” pattern of the base, an engineering trick to eliminate structural noise and vibrations to facilitate accurate data collection while also referencing Nike’s history and how its waffle soles revolutionized running shoe performance.

Straight from research to testing: the NSRL has a regulation basketball court, a track, a soccer field, and connects directly to the 100-meter outdoor track (with a gradient of 15.63%); it also has one of the world’s largest motion-capture installations (with 400 cameras), 97 force plates and body mapping equipment.

“In a way this project is like the culmination of a career spent pursuing authenticity – in architecture, in systems, in materials,” Tom Kundig continues, “I’ve always felt the basis of architecture is function-driven with a poetic finish. The physicality and athleticism you see in this building is something I’ve been exploring throughout my career at a variety of scales.”

The firm’s design cohesiveness is also on display in the interior design choices, which are deliberately rough and simple — concrete walls that have signs of construction work, plywood tables that become work benches — underscoring the research’s practical nature. The overall design of neutral tones is warmed up through powerfully communicative, motivational graphics, referring to Nike’s history and that of “King James” (in the public spaces).

Research, top performance, athleticism. And LeBron James Innovation Center also embraces sustainability. It is the second-largest LEED-NC v2009 Platinum building on the West Coast, with sustainability strategies including passive ventilation, daytime lighting through the central atrium and a photovoltaic system, in addition to the use of local materials and water-saving mechanisms.